| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Price : | 0.03-0.5 |

| Payment Terms : | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability : | 1KK/M |

| Delivery Time : | 5-7days |

| Brand Name : | RFan |

| Model Number : | RH04-84 |

| Certification : | UL.TUV.ROHS |

RH04-84 Holding 58℃ Fusing-Off 82℃ Thermal Fuse For Electronic Equipment Circuit Overheating Protection

2,Applications

This product is suitable for all kinds of electronic equipment circuit overheating protection,

widely used in motors,copiers,fax machines,HID ballasts,fluorescent lighting ballasts,

transformers,chargers,battery pack,heating appliances,Hair dryer,electric cooker,electric

kettle,electric kettle,coffee pot,ventilation fans,electric fans,electric sewing machines,water heaters,power converters,power plugs,refrigerators,air conditioners,car air conditioners,

instruments and equipment

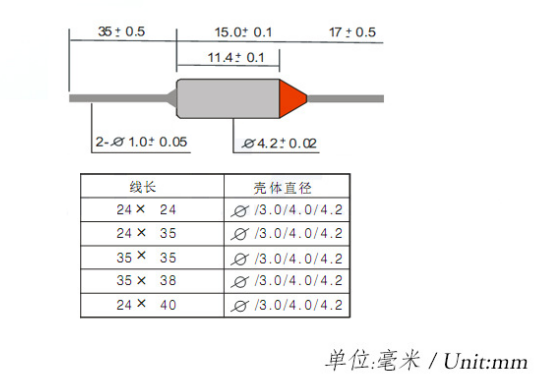

3,Appearances and Configuration

3.1 There shall not be any remarkable stain and crack on the appearances,markings shall be easily legible.

3.2 Configuration:Axial Leaded Miniature thermal cutoff Fuse.

4,Material Details

| NO. | Part Name | Material |

| ① | Sealant | Epoxy |

| ② | Lead Wire | Tinned copper wire |

| ③ | Case | Copper plated silver |

| ④ | Spring | Compression/Trip Spring |

| ⑤ | Bushing | Ceramic bushing |

5,Testing performance:

5.1 Tf-Rated functioning temperature

The temperature at which a Thermal Cutoff changes its state of conductivity to open circuitwith

detection current.The tolerance according to IEC691 is+0/-10℃

5.2 Fusing-off temperature:The fusing-off temperature indicates valuemeasured in silicon oil with a temperature increased by 0.5-1℃ per minute and a detective current 0.1 ampere or less.

5.3 Tc -Holding temperature:

The maximum temperature at which a Thermal Cutoff will not cause a change in state of conductivity to open circuit while conducting rated current for 168 hours.This rating is required by safety standards based on IEC691.

5.4 Tm -Maximum temperature limit:

The maximum temperature at whicha Thermal Cutoff canbe maintained for 10 minutes without re-

closing.This rating is required by safety standards based on IEC691.

5.5 In -Rated current

The allowable maximum current which a Thermal Cutoff is able to carry.

5.6 Un -Rated voltage

The allowable maximum voltage which a Thermal Cutoff is able to be applied.

6,Testing performance

| Test item | Specification | Test condition | Note |

1.Fusing-off temperature | Tf:+0/-10℃ | Silicon oil bath Temperature increased 0.5-1℃ per minute,detect current 10mA. | Sample size 25pcs per 25Kpcs or 50pcs per 50Kpcs |

2.Insulation resistance | D.C.500V 20MQ or above. | Between lead wires after fusing-off. | Sample size:25pcs per 25Kpcs or 50pcs per 50Kpcs |

3.Dielectric voltage withstanding test | 1000V+2倍额定电压, 1分钟 1000V+2timesthe rated voltage,1 min. | Between lead wires after fusing-off | Sample size:25pcs per 25Kpcs or 50pcs per 50Kpcs |

4.Torsion resistance test | No damage to the lead wire or sealant | Bend the leads into 90°angle,with one lead at 8mm from resin and the other lead at 5mm,then retort 180°once. | Sample size.5pcs per 25Kpes or 0pcs per 50Kpcs |

5.Pull test | No damage to the lead wire or sealant. | 1.5lb,1 min | Sample size:5pcs per 25Kpcs or 10pcs per 50Kpcs |

6.Appearance | Case;printing;lead wires | Visual inspection | 100%inspection |

Judgment:products should pass all the tests.Test records should be kept at least 2 years.

7,Product parameters

Product No. | Rated Functioning temp Tf(℃) | Fusing-Off Tf(℃) | Holding Tc(℃) | Max Temp Tm(℃) | Voltage AC(V) | Current(A) |

| RH04-73 | 73 | 70±2 | 45 | 150 | 250 | 16/15/10 |

| RH04-77 | 77 | 76+0/-4 | 51 | 150 | 250 | 16/15/10 |

| RH04-84 | 84 | 82±2 | 58 | 150 | 250 | 16/15/10 |

| RH04-94 | 94 | 91±3 | 66 | 150 | 250 | 16/15/10 |

| RH04-99 | 99 | 96±2 | 71 | 150 | 250 | 16/15/10 |

| RH04-104 | 104 | 100±2 | 79 | 150 | 250 | 16/15/10 |

| RH04-113 | 113 | 109+3/-1 | 84 | 150 | 250 | 16/15/10 |

| RH04-117 | 117 | 115±2 | 92 | 160 | 250 | 16/15/10 |

| RH04-121 | 121 | 119+2/-3 | 94 | 160 | 250 | 16/15/10 |

| RH04-133 | 133 | 129±2 | 104 | 160 | 250 | 16/15/10 |

| RH04-142 | 142 | 139+2/-3 | 114 | 160 | 250 | 16/15/10 |

| RH04-157 | 157 | 152±2 | 127 | 172 | 250 | 16/15/10 |

| RH04-172 | 172 | 169+3/-1 | 144 | 189 | 250 | 16/15/10 |

| RH04-184 | 184 | 182+2/-3 | 159 | 210 | 250 | 16/15/10 |

| RH04-192 | 192 | 188±3 | 170 | 250 | 250 | 16/15/10 |

| RH04-229 | 229 | 226+3/-2 | 200 | 250 | 250 | 16/15/10 |

| RH04-240 | 240 | 235±3 | 200 | 300 | 250 | 16/15/10 |

|